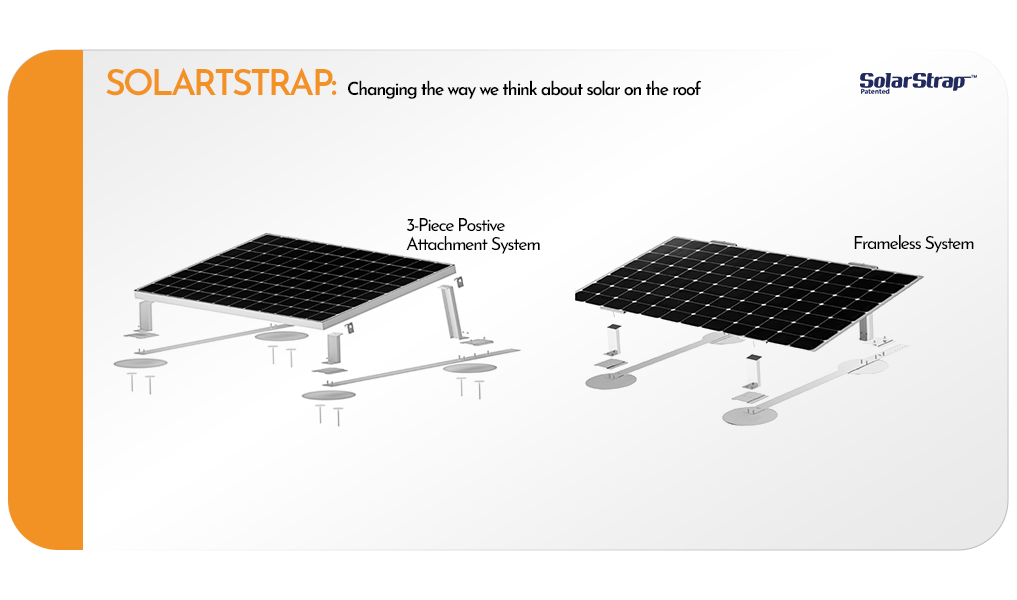

The SolarStrap™ roof attachment system offers a revolutionary advancement in mounting technology for PV system on flat roofs

The SolarStrap™ requires neither penetrations nor ballasts, while being both easy to install and attractively priced. A proprietary design employs heat sealing technology to secure the framework to the roof and allows for rapid installation with minimal tools.

People love solar, but no one wants to risk roof damage with a heavy ballasted or penetrating installation. So PermaCity invented a unique technology that lets us build without a single roof penetration or ballast block. It’s called SolarStrap, and it’s unlike any other solar mounting solution on the market.

SolarStrap is a racking system that sits gently on your roof with a downforce of only 2.0 psf. For most new roofs, it never penetrates your building and requires no heavy mounting structures that stress your roof. Its innovative, patented design employs heat sealing technology to secure the framework to the roof, enabling fast installation with minimal tools.

Designed and built in the U.S.A., the SolarStrap is pre-assembled to help with installation and labor costs. It’s compatible with most solar modules, accommodating roof pitches ranging from 0 to 15 degrees.

“Local solar systems are like mini power plants that generate power right where it is being used, saving on transmission costs and taking advantage of the city’s abundant sunshine to help meet electrical demand.” - David Wright, LADWP General Manager

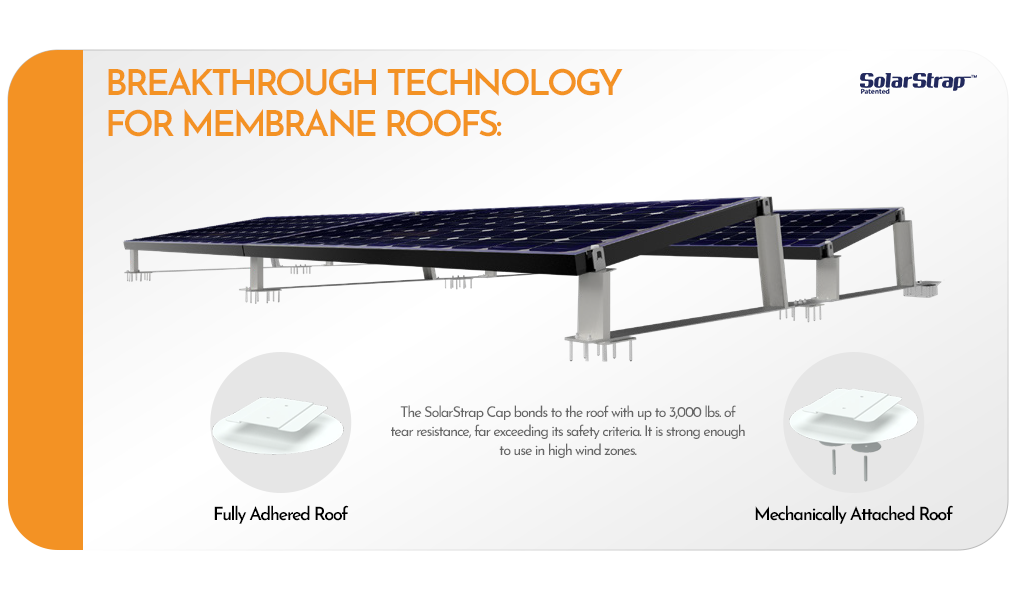

SolarStrap provides a universal technology that’s suitable for flat roofs of all sizes—whether you’re deploying one module or 60,000. It's specifically designed for modern roofs and doesn’t rely on ballast or seismic anchors, which aren’t suitable for lightweight materials. Instead, our patented connection “Cap” on membrane roofs secures each installation without penetrations that cause leaks.

OUR TECHNOLOGY IS ICC APPROVED AND UL CERTIFIED

PermaCity applies its own proprietary International Code Council (ICC) test criteria to SolarStrap installations, making building permits fast and simple. We ensure that our system clears maximum uplift forces and naturally provides extreme safety for earthquake bracing. Our installations comply with the International Code Council (ICC) to a minimum safety factor of five. This means that we test our system to withstand five times the maximum expected wind and earthquake pressure. The result is a uniquely strong yet flexible solar deployment that helps protect the roof and maintain its warranty.

Designed for tough conditions, SolarStrap is also suitable for all types of asphalt roofs and can be installed in minutes with no wasted parts. For asphalt roof installations, we employ a flat stanchion instead of the Cap and Tie to secure the solar panels. This approach is ideal for asphalt roof materials that are not as strong as membrane roofs. The flat stanchion screws into the roof membrane, providing high safety thanks to SolarStrap’s trusted design.

The Cap sheet is heat-welded over the stanchion, bonding with the roof. Screws are fully covered and bonded to the roof to eliminate leakage, streamline permit processes, and minimize owner concerns.

.png)

.png)